| Power Supply | 220–240VA C 50/60Hz, 15A |

| Microwave Source | 2450MHz, dual magnetron high energy microwave |

| Complete installation power | 3200W |

| Microwave maximum output power | 2200W, microwave non-pulse continuous automatic frequency conversion control |

| Display | Super large 7" touch LCD display |

| Software system | ARM chips equipped with ZGI operating system | ARM chip equipped with ZGI operating system, three-level management, audit tracking, mouse support | ARM chip equipped with ZGI operating system, three-level management, audit tracking, mouse support |

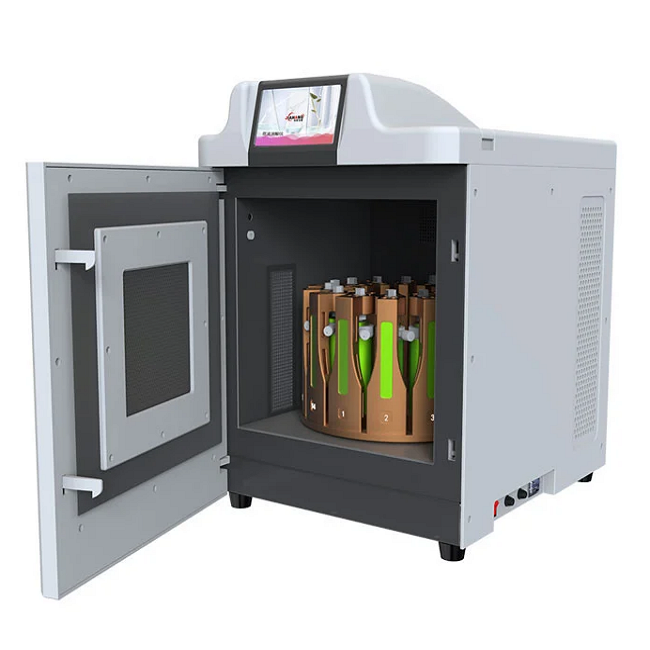

| Microwave oven cavity | 65L large volume 316L stainless steel chamber, internal & external multi-layer corrosion resistant PFA Teflon spray |

| Temperature control system | Real-time inspection control and display of temperature and curves in all reaction tanks | Real-time inspection control and display of temperature and curves in all reaction tanks | Dual ZG Dual-beam multi-objective temperature control system, real-time detection control and display of temperature and curves in all reaction tanks |

| Safety explosion-proof door design | Eight-layer steel structure, self-ejection explosion-proof buffer (AUT-relief), electronic & mechanical double safety protection |

| Pressure control system | G-pressure monitors all reaction tank pressure in real time, adjusts/stops microwave emission, alarms over overpressure, range: 0–1600psig |

| Pressure Measurement System | Piezoelectric pressure sensing, range: 0–16MPa (2500psi), accuracy ±0.1MPa |

| Temperature Measurement System | High precision optical fibre sensor, measuring range: -50–350°C, control accuracy ±0.1°C, display accuracy 1°C |

| Video surveillance system | Real-time monitoring of digestion tank via internal camera | Real-time monitoring of digestion tank via internal camera | Equipped with 7" LCD screen, real-time monitoring of digestion tank via internal camera head |

| Whole tank pressure passive protection system | ZG infrared temperature monitoring, range: 0–350°C, accuracy ±0.1°C |

| Whole tank temperature monitoring system | Top safety pressure relief device, overpressure quantitative directional automatic relief |

| External network interface (optional) | USB, RS-232 |

| Sample reaction tank outer tank | Aerospace composite fibre material explosion-proof outer tank |

| Furnace cavity exhaust system | High-power corrosion-resistant axial flow fan, turbulent and efficient air cooling, 200°C to 60°C in 15 minutes |

| Working environment (temperature/humidity) | 0–40°C / 15–80% RH |

| Physical dimensions & Net weight | 580 × 680 × 720mm (W×D×H), 65kg |